Beveling & Chamfering Machines

Precision Edge Preparation for Welding and Fabrication Efficiency

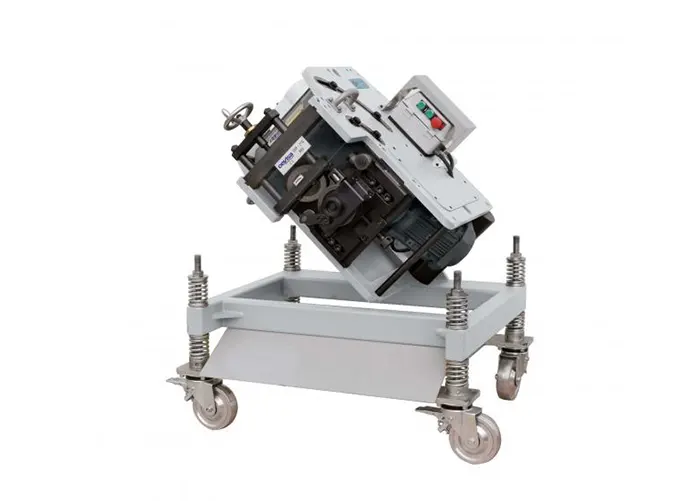

Fenatek’s range of Beveling and Chamfering Machines is designed to deliver clean, accurate edge preparation for plates, pipes, and metal sheets before welding or assembly. Built for performance and durability, our machines combine advanced shear and machining technologies to create perfect bevels, improve weld penetration, and reduce manual grinding work. Whether you’re working on structural steel, heavy fabrication, or pressure vessels, Fenatek ensures consistent results that enhance productivity and quality across every job.

With models ranging from standard and gradual beveling systems to reversible and thick-material machining units, Fenatek provides solutions for every industry. Each beveling machine is engineered to achieve smooth, uniform chamfers with zero distortion — even on complex geometries and large plates. Combined with easy handling, minimal maintenance, and immediate readiness, these machines are your go-to tools for efficient, repeatable, and high-quality bevel preparation.

APPLICATIONS

Fenatek beveling and chamfering machines are widely used in steel fabrication, shipbuilding, construction, pipeline manufacturing, and heavy engineering industries. They are ideal for preparing edges on carbon steel, stainless steel, aluminum, and other alloys prior to welding or coating.

By ensuring accurate bevel geometry and a clean, burr-free surface, these machines improve welding quality, reduce filler consumption, and minimize operator fatigue. Whether for structural components, pressure vessels, large plates, or custom fabrications — Fenatek beveling machines guarantee precision, safety, and long-term reliability for every industrial need.

Standard beveling machines

Standard shear beveling machine CHP-12

CHP-12 INV beveling machine

Standard shear beveling machine CHP-7

Gradual beveling machines

CHP-21G gradual shear beveling machine

CHP-12G gradual shear beveling machine

CHP-21G INV gradual shear beveling machine

Reversible beveling machines

CHP-12G REV reversible shear beveling machine

CHP-21G REV Reversible Shear Beveling Machine

Large thicknesses

CHP-30G beveling machine

CHP-60G thick machining beveling machine