Pipe Beveling Machine

Where Is A Pipe Beveling Machine Used? freopen -Pipe beveling machines are found in the industries which require pipe cutting and beveling with higher degree of accuracy earlier it was not possible at that level. Crafted for high deposition rates, with easy weld preparation and smooth feeding in difficult environments. Whether you are working with small pipe or large pipe, there is a pipe beveling machine that meets your needs and will improve productivity and reduce costs.

Designed for the toughest of applications, these machines are among the best in the business and will deliver excellent performance if maintained properly. Their advanced designs provide maximum reliability and ease of use ideal for professional use where accuracy is needed in every measurement.

Applications

Pipe beveling machine that is used in heavy duty industries to get the perfect end-output of the pipes for welding purposes.

- Oil and Gas: These machines are extensively utilized in oil and gas industry to generate correct bevel angles on the pipes prior welding, for perfect weld penetration & leak-free joints in pipelines, refineries & offshore projects. Good beveling can reduce the defect of weld and improve the service life of products, which will pipe under Causes extreme pressure, temperature, vibration and bending.

- Construction: If you need to prepare slightly larger industrial or commercial pipe and tubing, they can be a fantastic component of construction tools that assists with building structural supports, plumbing connections and fire protection elbows by producing perfectly cut edges for easy instillation arrangements and faster welding or fitting operations.

- Shipbuilding: The shipbuilding industry makes extensive use of pipe beveling machines when it comes to getting pipes used on propulsion systems, fuel lines, cooling circuit and on-board services ready because precision and durability are crucial to withstand rough conditions at sea.

- Power Plants: whether at thermal, nuclear or renewable installations — these machines are used to prepare pipes that help to carry steam lines, boilers and cooling systems, creating strong welds that can withstand high heat and consistent use.

- Manufacturing: pipe beveling machines contribute to productivity by providing quick, consistent bevels on many pipes in a short amount of time and are also crucial for achieving structures that can lead to efficient fitting of sections with trustworthy overall quality and minimised rework across numerous types of fabrication coverage.

Advantages of Using Pipe Beveling Machines

Spending less time and significantly reduced manual labour to prepare welds.

- Obtain excellent cutting performance with a very clean cut quality.

- Adjust settings for different pipe sizes and materials.

- Reduce operator fatigue with ergonomic and well-balanced designs.

Solutions we provide

"Saddle-Type" Beveling Machine

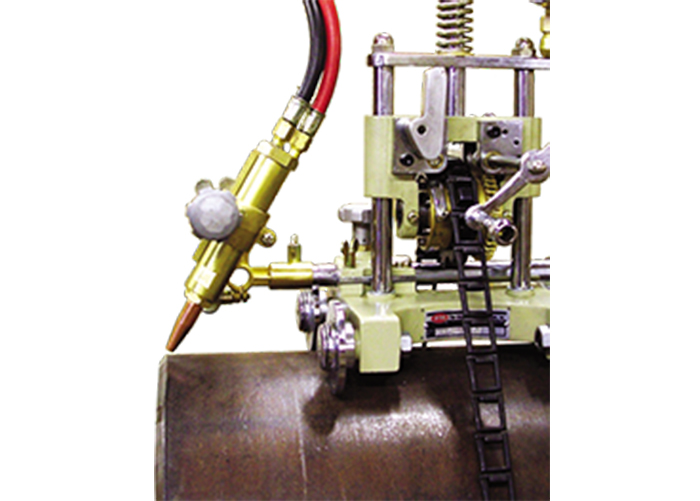

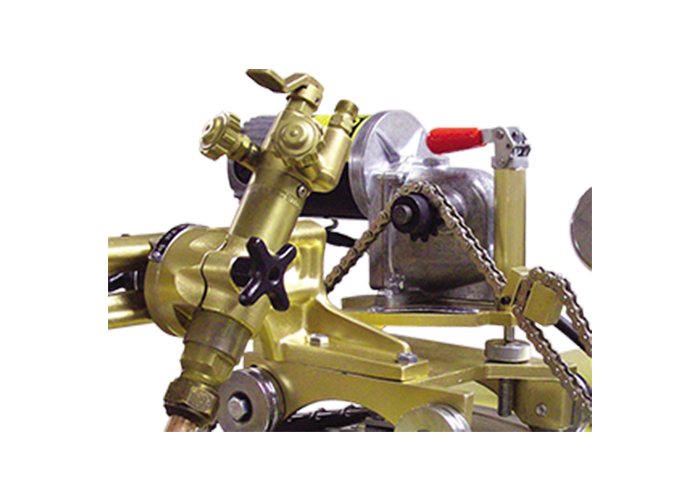

Standard "Saddle-Type" Beveling

4 Wheel Heavy Duty Motorized Beveling

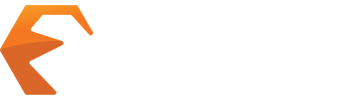

Band-Type Beveling Machine