Magnets for Positioning and Holding

Magnetic positioning and holding solutions are revolutionizing industries by providing efficient, reliable, and precise tools for aligning and securing materials in various applications. These tools leverage the power of magnetism to streamline processes in metal construction, switch cabinet assembly, sawing, deburring, and beyond. At Fenatek, we pride ourselves on offering world-class magnetic tools and solutions sourced from industry leaders like Strong Hand Tools. Our range of magnets for positioning and holding ensures enhanced productivity, precision, and safety for our clients.

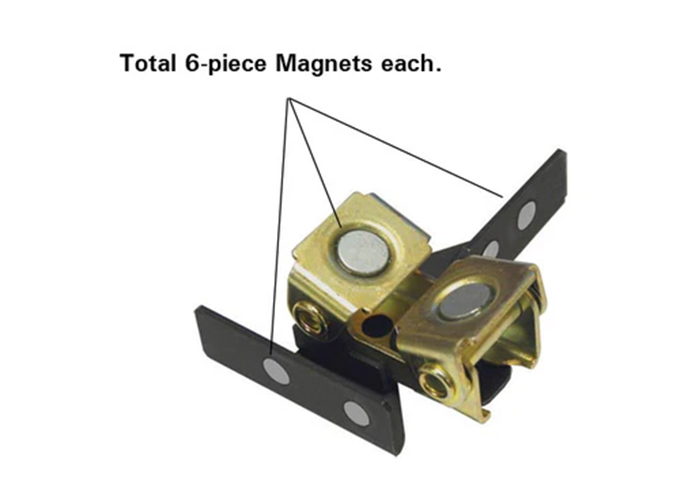

Magnetic positioning is the process of using the unique magnetic fingerprint of materials to map, align, and secure components during assembly or fabrication. Our product are the most efficient, most versatile available whether lifting thin gauge sheet metal or positioning medium density material in place. With options ranging from strong lifting magnets suitable for loads of as much as 490 kg, to lightweight tools, perfect for tack and sub-assembly work, the range Fentek’s products has most applications covered.

Applications

Our magnets for positioning and holding are ideal for:

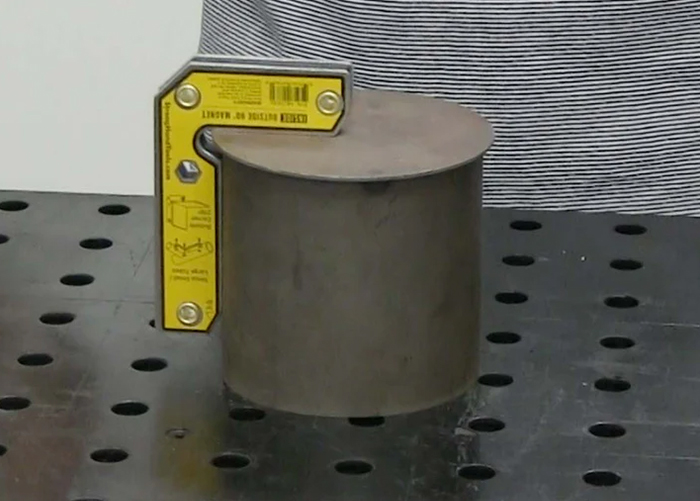

- Metal Fabrication: Align and hold steel plates, pipes, and irregular shapes with ease.

- Welding: Tack weld materials securely while keeping inside areas accessible.

- Load Handling: Lift thin and heavy sheet metals with confidence using our TML magnets.

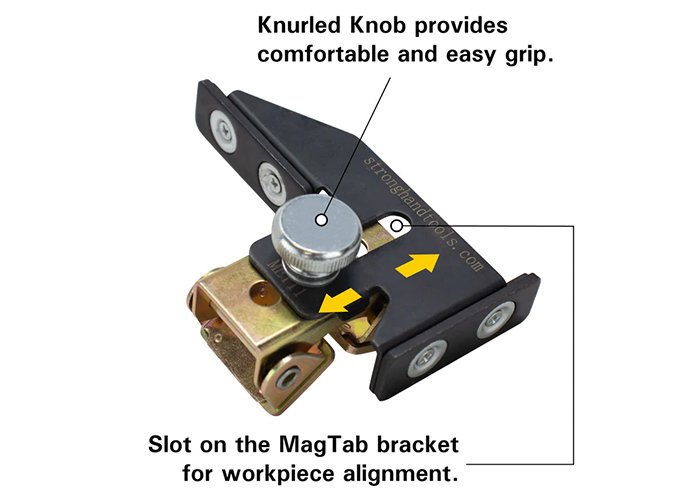

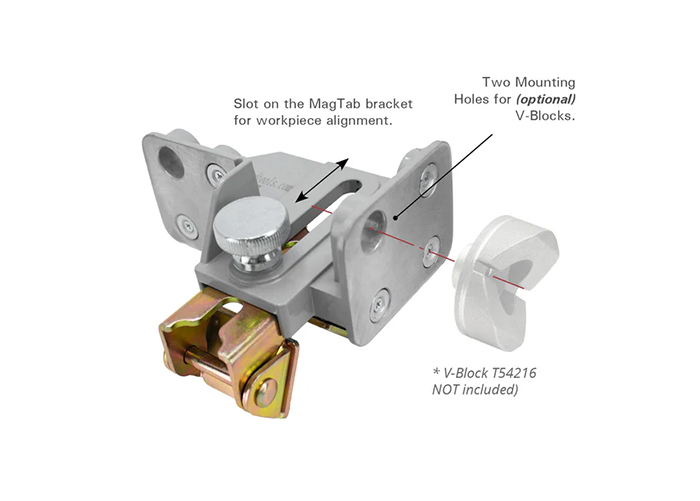

- Assembly Work: Build and position lightweight structures with precision using MagTabs and V-Pads.

- Construction: Secure materials during sawing, deburring, or switch cabinet installations.

- Field Applications: Portable and durable solutions for on-site fabrication and repair.

Why Choose Fenatek?

- Superior Products: A partnership with Strong Hand Tools guarantees you are receiving the highest-quality product available.

- Personalized Advice: When it comes to magnets for lifting, holding and positioning, we give you our personal advice based on your challenges.

- Expert Assistance: Contact our experienced team to help you pick the best tools and for advice on integration into your routines.

- Lifetime Free Service: A simple promise to our customers is we provide all products long life free service, make these values for lifetime and peace of mind.

Improve your metalworking accuracy with these FENATEK Magnets For Positioning & Holding at Saudi Arabia These magnets are designed to provide fast, secure magnetic clamping for fabrication, welding, assembly applications and more! Our MPIs and positioning magnets are engineered to maintain a strong hold on magnetized ferrous objects, allowing for precision alignment and secure lifting of steel plates, profiles or parts. So, whether you’re in the business of steel fabrication tasks associated with structural building, industrial manufacturing assembly line work, or for heavy workshop purposes – Fenatek’s magnetic solutions simply help keep your work moving along using less man hours to accomplish. Made with high-quality magnetic materials and an IP-covered strong housing with ergonomically friendly design, these magnets are easy to use and offer consistent holding force year after year at the Kingdom of Saudi Arabia for welders, fabricators and maintenance technicians.

Fenatek’s push and hold magnets are adjustable and have a variety of configurations to meet your precise working requirements, they can be permanent for energy-free clamping, or adjustable magnetic holders which if used in pairs enables the operator to fine tune part positioning. Our magnetic products are perfect for tack welding, tool and jig holding, even working around corners or on curved surfaces too when multi-sided contact is required. When combined with a powerful magnetic force, it provides reliable retention in the most demanding of applications and operator safe release functions maximises safety to transitioning work pieces safely between qualified tooling. Fenatek magnets, the ideal solution for fabrication workshops, metal working plants and construction sites throughout the Saudi market – a name you can trust to deliver true value and after sales back-up. Once you incorporated these magnetic clamping tools into your manufacturing process, labour costs will be minimized, throughput maximized and the same high precision standard of production will be ensured. Discover our full range of magnets for placement and holding to find the magnetic solutions you need to drive your metal working efficiency and productivity in Saudi Arabia.

Solutions we provide