Pipe Grinding Machine

Pipe Grinding Solutions Brought To You ByFENATEK At Fenatek, we also specialise in market leading and efficient pipe grinding solutions. Our machines are state of the art in design, technology and features for all-metal pipe products (round, oval or irregular) that make them become much sought-after machines for process and tube shops alike. It doesn’t matter if you are working with iron or stainless steel; our pipe grinding and polishing machines can handle it.

Applications of Pipe Grinding Machines

- Industrial piping systems: these machines are widely used for preparing welds, to deburr or polish the tubes and pipes at ends, thus providing a clean finish prior to joining. Optimal grinding enhances joint quality and increases leakages resistance as well as the corrosion protection that play a particularly significant role in industries such as oil & gas, chemical processing, power generation and water treatment.

- Decorative metalwork and custom fabrications: our pipe grinding machines are the perfect solution for working with stainless steel, aluminum and other metals like brass or bronze on curved or straight surfaces such as gates, handrails, furniture frame..88231 – wwcs. These allow fabricators to achieve uniform textures for visually appealing surfaces, irrespective of being required to finish them with a mirror or brushed polish.

- Automotive and aerospace components : News Pipe Grinding Machines in the automotive industry roll cages and hydraulic lines as well as pipe for heat exchangers, waste oil lines and a whole variety of applications where difficult to grind material is found on this machine. Precision grinding results in precise part tolerances and reduces any stress points & load points, improving the durability and longevity of parts.

- Building and construction projects: these tools facilitate overall pipe and structural pipe fitting in building& construction installation. With these advantages, it’s no wonder why pipe grinding machines are must-haves for contractors looking for strong joints, shorter installation times and a quality finish; from modern fabrication facilities to construction overhauls.

Why Choose Our Pipe Grinding Machines?

- Wide Range of Applications: Fit for straight and curved pipes

- Customizable Finishing Options: Satin or surface grinding.

- Exceptional Precision and Durability: Advanced orbital sanding technology.

Invest in Fenatek’s Pipe Grinding Machines to elevate your metalworking capabilities. Contact us at sales@fenatek.com today to learn more or to request a quote for our industry-leading grinding machines

Image Gallery

1

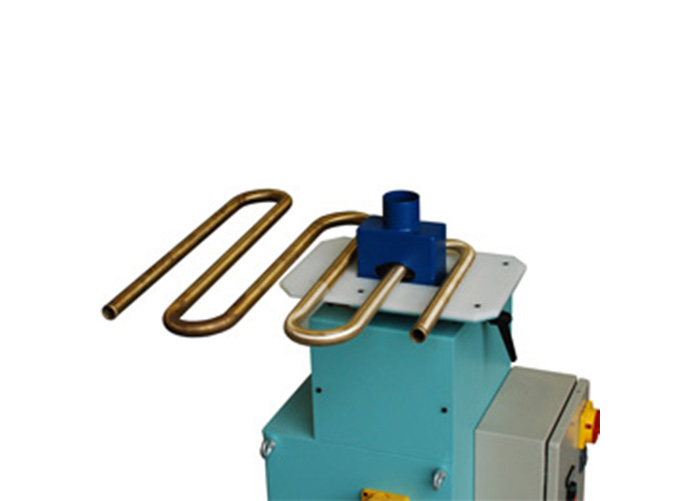

Optimal Pipe Diameters From 5 mm to 203 mm for various industrial applications.

2

Flexible Radius ControlAdjustable radius settings for precision grinding and polishing.

3

Energy EfficiencyLow power consumption without compromising output.

4

Durable ComponentsBuilt for long-term reliability in demanding environments.

5

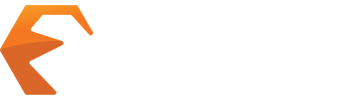

Customizable Processing ModesOptions for wet and dry grinding to suit different material requirements and ensure efficient operation.

6

High-Performance Abrasive BeltsEquipped with durable abrasive belts for consistent results and extended usage across multiple applications.

Pipe Grinding Machine