Sandwich ,Cladding Panel Lifters

Cladding vacuum lifters are the tools that have been designed for the safe transportation of cladding panels to the desired locations, not only in construction, but also in architecture and industrial applications. Through the use of advanced vacuum suction technology, these lifters tightly adhere to the panel surface, leading to a careful and damage-free installation of the panel.

Our vacuum lifters are the result of concentrated R&D efforts of our engineering team and are capable of handling a variety of panel sizes and weights – right from the very light ones to the very heavy which both kinds correspond to the types of sandwich panels that are to be used in roofing as well as in wall installations. So, the user engineer can adjust the machine in a way that it can work with either very light or extremely thick panels by changing the parts or adjusting some other settings.

Looking for the right vacuum lifter for your cladding or sandwich panel needs?

Optimize your façade installation and material handling with Fenatek Cladding Vacuum Lifters in Saudi Arabia, engineered to provide safe, efficient, and precision lifting of cladding panels across construction and architectural projects. Our cladding vacuum lifters are designed to handle a wide range of panel materials — including aluminium composite panels (ACP), stone, glass-reinforced concrete (GRC), natural stone, and other heavy façade elements — with outstanding suction performance and stability. Built for the rigours of modern building sites, these vacuum lifters significantly reduce manual handling, minimise the risk of damage to valuable cladding materials, and improve overall site safety. With robust construction and certified vacuum systems, Fenatek’s cladding vacuum lifters offer dependable performance, making them an essential solution for contractors, façade installers, and general contractors operating throughout Saudi Arabia.

Fenatek’s cladding vacuum lifters deliver flexibility and productivity tailored to your project needs, whether you require battery-powered units for on-site mobility or electric models for continuous workflow in industrial applications. Featuring ergonomic controls, adjustable suction pads, and options for tilting and 360° rotation, our vacuum lifters make precise positioning and installation of large cladding panels easier and faster — even in tight or elevated spaces. Designed to integrate seamlessly with cranes, gantry systems, and overhead lifting solutions, Fenatek’s range supports faster cycle times, reduced labour costs, and enhanced operational efficiency. Backed by expert after-sales service and optional customisation based on panel size and weight requirements, our cladding vacuum lifters are the go-to choice for businesses looking to enhance productivity while maintaining the highest standards of safety and quality in façade installation. Explore Fenatek’s complete vacuum lifting solutions in Saudi Arabia to find the right cladding lifter for your application and elevate your project outcomes.

Contact our team at sales@fenatek.com — our experts are ready to help you choose the perfect lifting solution tailored to your business requirements.

Cladding Vacuum Lifter Options

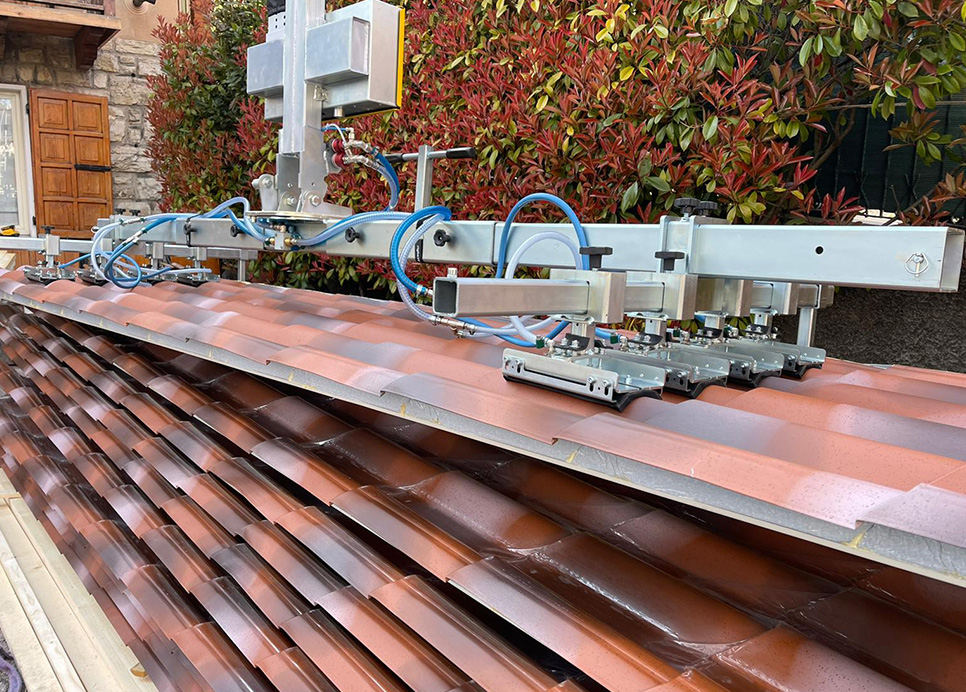

Cladding Vacuum Lifter for insulated panels

Battery-powered cladding lifters

Electric Cladding Lifters

Pneumatic Cladding Lifters

Fixed Frame Lifters for Large Panels