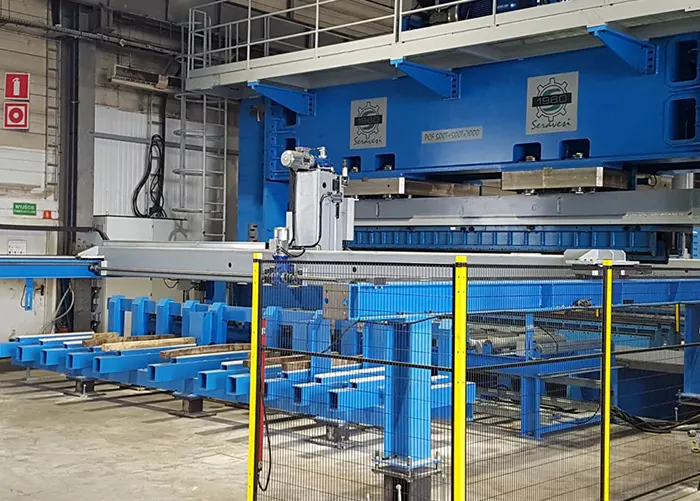

Hydraulic Dishing Presses

Our Hydraulic Dishing Presses are by 1960 Seravesi, and these robust presses have been developed for precision metal forming, being both powerful and long-lasting. These presses are offered in multiple designs including fixed and moving gantry-style models with the power to meet the most challenging industrial requirements. Featuring a high-performance hydraulic system and powered by reliable Kubota engines, the U25-3 offers exceptional manoeuvrability and digging force. Our hydraulic presses are built for forming dished ends, making corrugated panels, and perfecting other metals and aren’t limited to metalforming applications like our competitors.

Built for custom-manufacturing capabilities, today’s presses are suited to a range of industries such as shipbuilding, metal fabrication and heavy plate straightening. They are robust and have a long life while being easy to maintain thanks to their user-friendliness. From fixed-cylinder grease presses for dished end shaping, through to a mobile gantry press for flanging plates, our range of models are built with your specific requirements in mind throughput and dependability.

APPLICATIONS

- Dished Ends Manufacturing – Offers the shaping of dished ends for pressure vessels, tanks, and industrial storage applications.

- Metal Fabriion – Great for profiling, straightening, and Letting manufacturing plate steel or welded structures.

- Shipbuilding –Ideal for fabricating precision and high strength structural parts.

- Corrugated Panel Forming –forming corrugated panels for the construction industry quickly and effectively.

- Heavy Plate Flattening –Grinding and smoothing heavy metal plate to match exact industry standards.

- Forged Bar and Welded Structure Straightening – For consistency and integrity of structure we straighten forged bar and…

TYPES OF HYDRAULIC PRESSES

Mobile Gantry Presses With Mobile Cylinder (PPM)

This press model is used for:

- Flattening of thick and large size plates

- Straightening forged bars

- Straightening long electro-welded structures

Fixed Gantry Press with Mobile Cylinder (PCM)

This press model is used for:

- Forming complex parts

- Forming corrugated plates

Fixed Gantry Press with Fixed Cylinder (PCF)

This press model is used for:

- Producing dished ends

- Forming complex parts

ADDITIONAL FEATURES FOR CUSTOMER BENEFIT

- CE Certified Design-Meets all international manufacturing safety & quality standards.

- Customizable Configurations – Available in fixed gantry, mobile gantry, and fixed/mobile cylinder options to meet specific production needs.

- Remote Monitoring & Troubleshooting – Integrated modem for remote PLC control and fault resolution.

- Efficient Cooling System – Air or water cooling options for hydraulic oil to maintain optimal operating conditions.

- Seamless Integration with Manipulators – Coordinated with auxiliary hydraulic manipulators to improve production efficiency.

Image Gallery